Nagoya Hagata’s die-cutting tools are created from a perfect balance of modern machinery and the skilled craftsmanship of our experienced technicians. Achieving absolute precision in every cut requires higher, more accurate, and more stable standards. Micron-level accuracy comes not only from long experience, but also from strong expertise and our constant effort to innovate.

Our dies stand out because of our production philosophy: We only start making a die when we fully understand the customer’s material and the level of precision they need. To truly support our customers, each die must match their production process — not just the drawings, but also the actual operating conditions and quality goals. We believe a “perfect die” is not only one that meets technical standards, but one that helps customers improve efficiency and create new value. Nagoya Hagata continuously pursues the most advanced cutting technologies, always pushing limits to stay ahead as a pioneer in the industry.

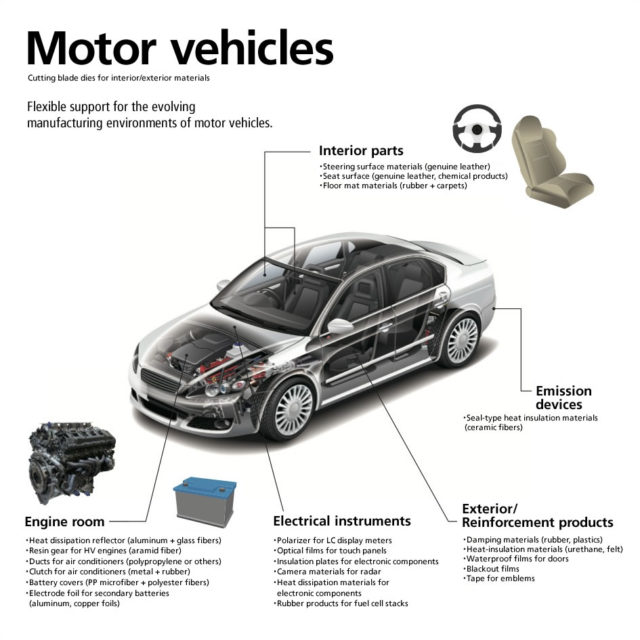

Illustrations of Typical products cut using Nagoya Hagata die-cutting tools

Supports the most-advanced manufacturing

The “one-and-only” technique in Nagoya Hagata is utilized in the variety of most-advanced manufacturing industries, such as aviation or space, automotive, fuel cells, medical products and equipment, cosmetics and hair-care products, IT materials, and high-performance optical films. We handle any products that require the application of cutting at some stage—any mold is the task we face.

Examples of materials we cut

PET films for engraving mold and precision Thomson mold specifications / Metal foils such as copper or aluminum / Cushion materials such as PORON® / High or low adhesive tapes / Conductive fabrics / Reflective seat / Polarizing films / Diffusers / Light guide plates / PP (polypropylene) / PC (polycarbonate) / Fluorine, Silicon rubber seating / aramid fibers / Carbon fibers / Lithium ion cells and more

Features of Our Products

-

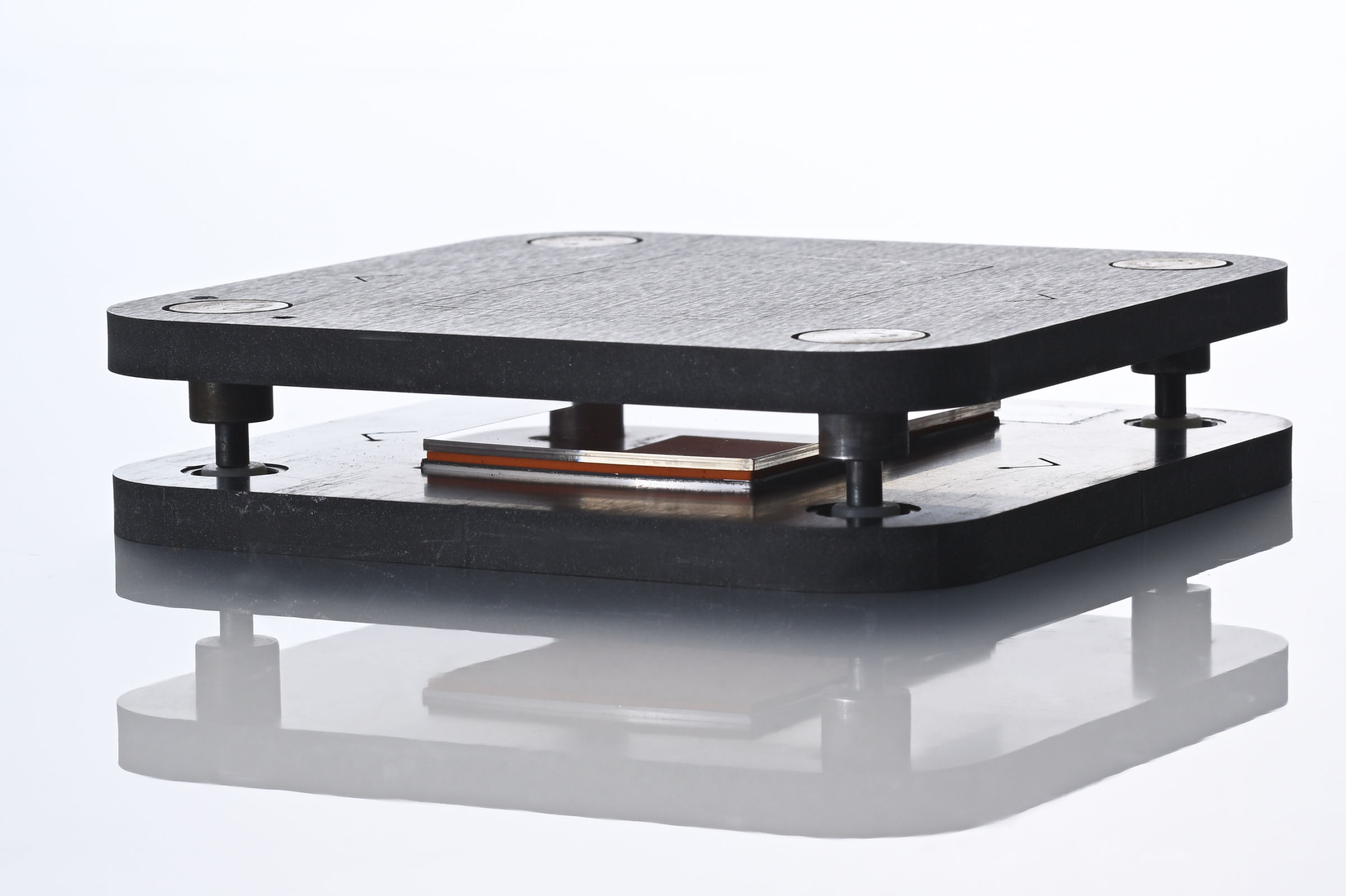

Our diminutive punching mold, 0.3 mm square

- Nagoya Hagata’s Thomson mold expertise has realized an extremely small punching mold, whose size is just 0.3 mm square.

- Using ultra-fine processing and kiss-cutting progressive mold technique, this ultra-small mold enables cutting only coatings of 5 to 10 μm thickness on a 15 μm base film.

- This is a cutting mold for press cutting for IT industry products requiring micro fabrication.

-

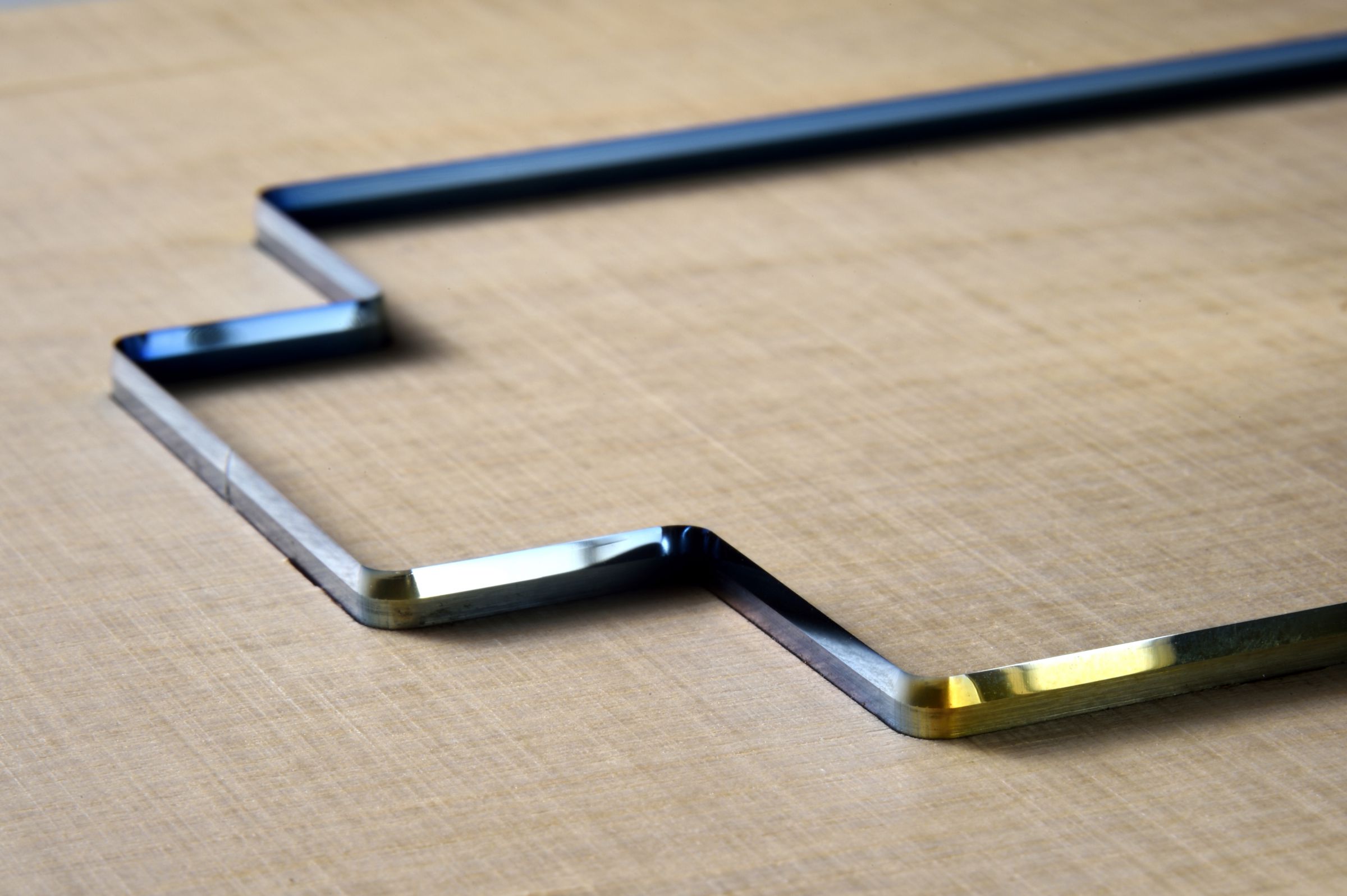

Double-sided die set (upper/lower cutting dies)

- Nagoya Hagata’s ultra-precision bending technology enables exceptional cutting accuracy, ensuring an extremely flat cut surface—even with thick plastics from 0.5 to 2.0 mm.

- A special blade-tip design eliminates the need for a metal backing plate, helping optimize production costs.

- Even when used for single-sided cutting, our dies can achieve an increased cut-surface thickness of at least 2 mm—a result verified at Nagoya Hagata.

-

Perfect hard-coating film cuts for smartphones and tablets

- Achieves smooth and refined cutting surfaces for hard-coating films and laminate films used in smartphones and tablets.

- Provides a comprehensive solution: eliminates micro-gaps, air bubbles, and cracks in both small and long holes, ensuring superior product quality.

-

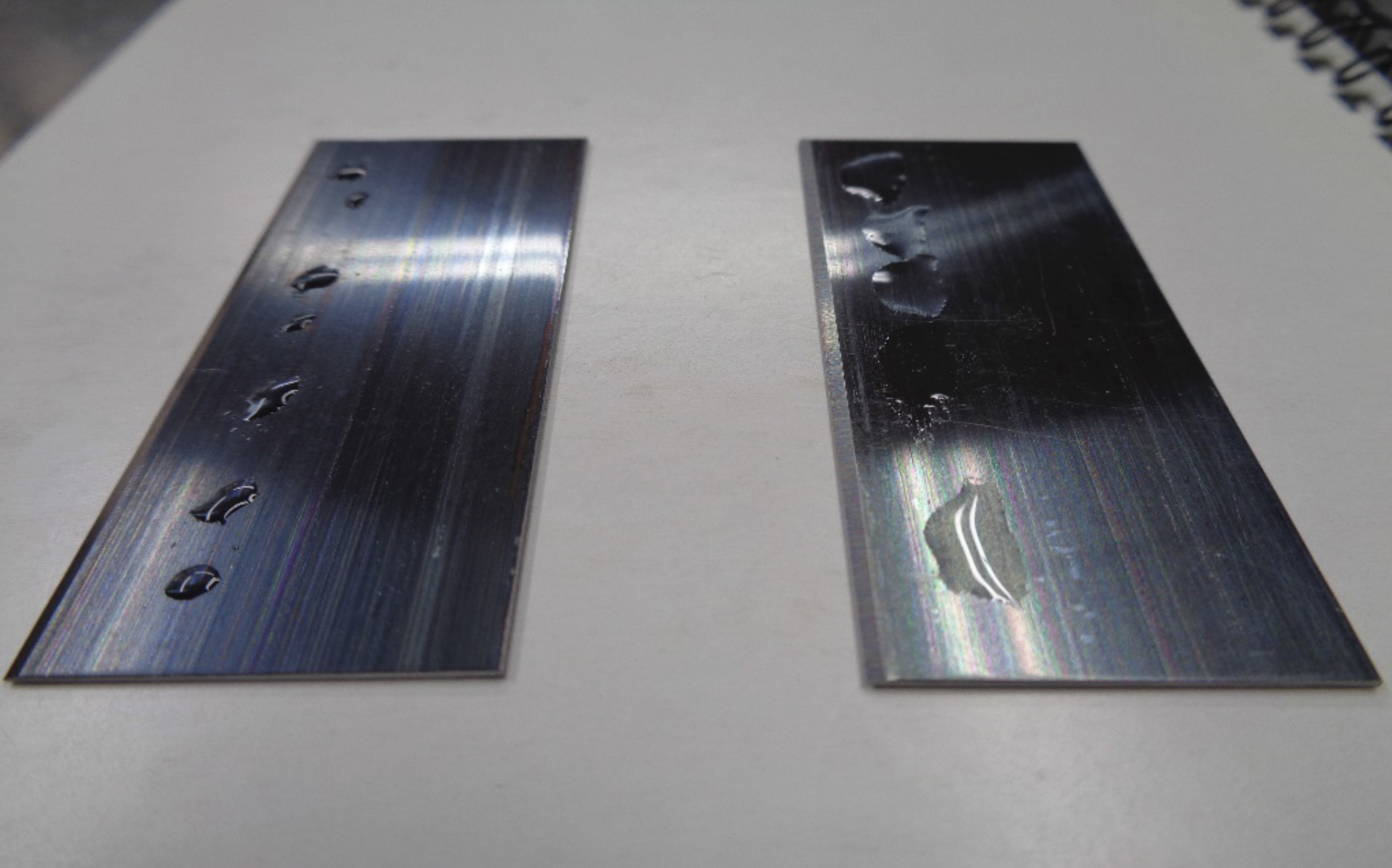

Die-cutting tools for Li-ion battery electrodes

Ensures precise, burr-free cutting for both the positive electrode (aluminum foil) and the negative electrode (copper foil). Enables in-process inspection and verification of cutting quality during testing, helping optimize production efficiency and ensure consistent product quality.

-

Non-adhesive (releasable) spray for cutting mold

- Environmentally friendly fluorine coatings for which the fluorine resin has the useful property of being releasable, work for non-adhesive applications in film cutting for electronic components.

- Use this spray, and you banish the problem of dust-adhesion to your cutting mold during film-cutting.

Cutting mold in Nagoya Hagata

-

RAIDE CUT mold

- For press cutting of IT related components

- Blade variation: 0.45 to 1.4 mm in thickness / 23.6 to 23.1 mm in height

Standard edge angle: 40° to 43° (center blade, single edge, fluorine edge, 30°, 60°, and 90° are also available) - There are also mirror-finish blades, with bespoke shapes as specifically ordered.

- It is also possible to cut thin films of only a few tens of micrometers in thickness.

-

Wire cutting mold

- A metal-processing method that uses a thin wire combined with electrical discharge to cut components.

- Achieves both ultra-high precision and excellent base hardness at the same time.

-

Swedish steel die