At Nagoya Hagata, we use advanced, industry-leading machines including precision analysis tools to support our high-accuracy mold manufacturing. By combining world-class equipment with the expertise of master engineers, we achieve the highest production results. Since our founding, “harnessing world-class machinery” has been part of our DNA. We continuously upgrade to the latest models so customers can verify the precision of our molds both visually and through accurate measurement. Here is a selection of the equipment we use.

Microscope

The microscope is used to examine the cutting capability of the blade at the molecular level. It analyzes the blade body, blade edge, and cross-sectional profile to ensure the highest quality during production. Customers may also conduct inspections to verify the analysis results.

- x1000 1set

- x200 1set

Automatic measuring machine

This device enables automatic size measurement, even for large materials. It helps ensure quality and supports Nagoya Hagata’s ultra-precision die-cutting tool production.

- Control resolution : 1μm

- Measurement precision : ±(50+10×L/500)μm

- Measurement range : 1,500×1,200mm

- Measurable height : 45mm

High-speed punching machine

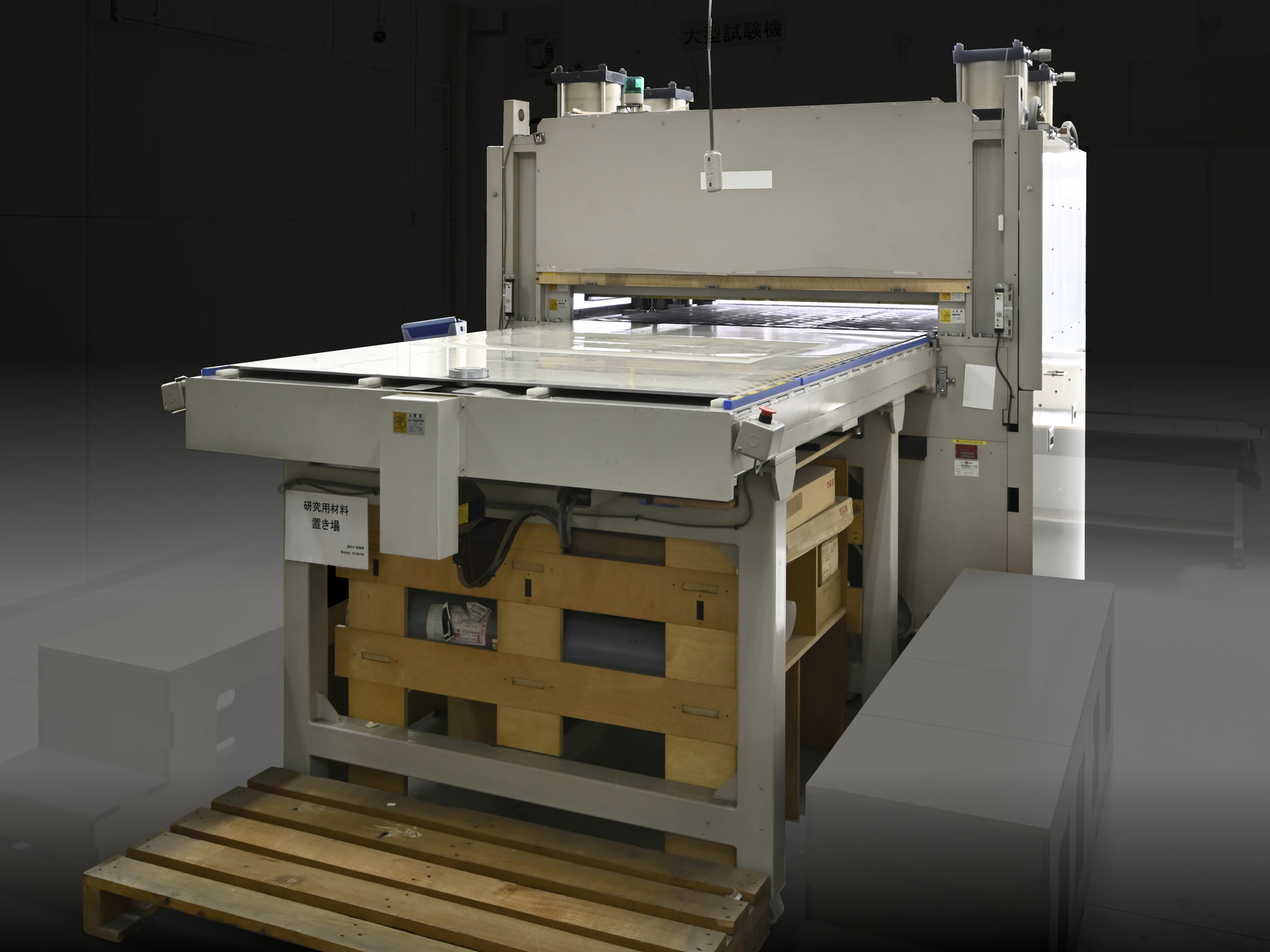

Large-size press machine

Trial punching and precision checking are available whenever needed.