Once a die is completed and delivers the expected cutting performance, quality concerns are virtually eliminated. At Nagoya Hagata, customers are welcome to visit our facility at the time of delivery to directly inspect how the die operates.

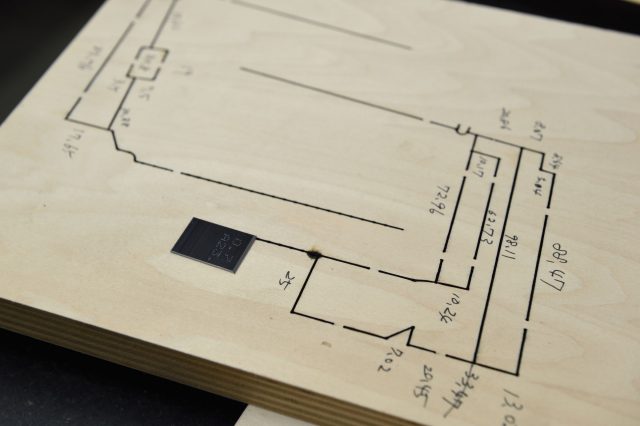

We perform on-site material cutting tests and conduct joint measurements with customers to transparently and clearly confirm accuracy. Additional in-depth inspections are also carried out, including:

- Microscopic analysis of the cut surface

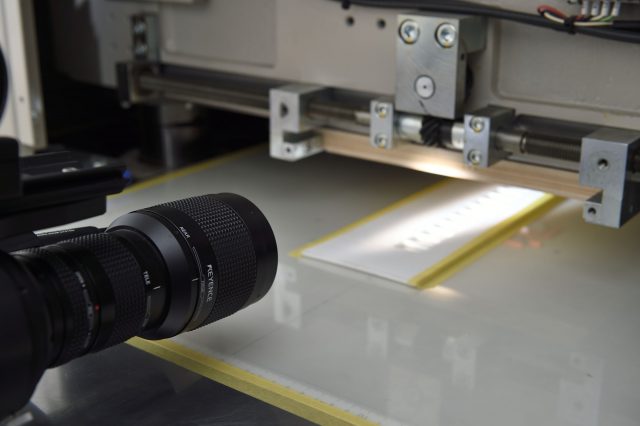

- High-speed camera imaging or video of the blade movement

- Comprehensive evaluation of key cutting parameters

These inspection procedures completely eliminate the need for customers to perform additional checks at their own factories, reducing confirmation time and ensuring total confidence when using our dies.

We are equipped with state-of-the-art analytical devices that allow us to meet even the most complex technical requirements. Nagoya Hagata has earned strong recognition from many customers, especially those working with uncommon materials such as new-generation or high-tech materials. Whenever adjustments are needed, our engineering team responds immediately, ensuring that all parameters are fully optimized on the spot. This meticulous attention to detail at every step is what enables us to deliver perfectly finished products with absolute, reliable quality.

This inspection service requires an advance reservation. Please use our Inquiry Form to make a booking.