| Company Name | Nagoya Hagata Inc. | |

|---|---|---|

| Address | Minami Obori 12, Higashi Itsushiro, Ichinomiya, Aichi, 494-0008 Telephone: +81-586-61-7722 Fax: +81-586-61-7772 e-mail cadwg@nagoya-cut.co.jp |

|

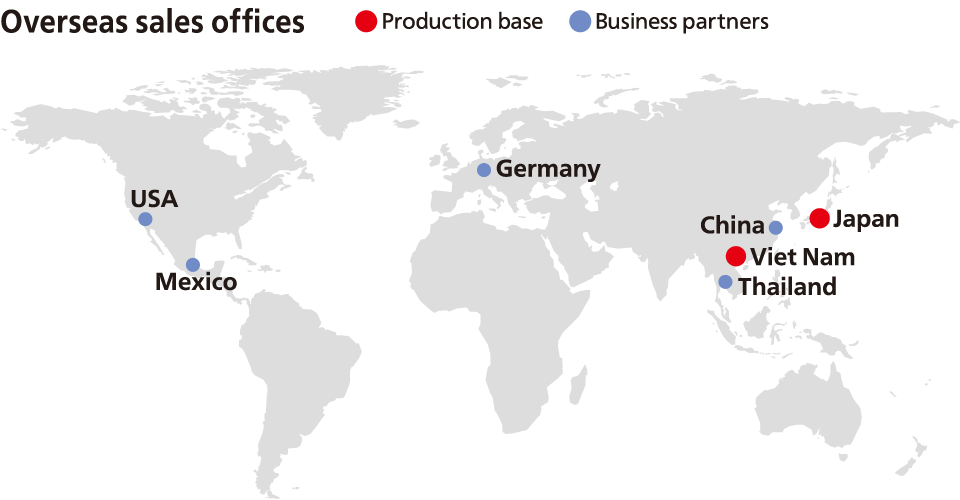

| NAGOYA HAGATA HANOI INC. Dong Van III Supporting Industrial Park, Dong Van Ward, Ninh Binh Province, Vietnam TEL. +84(0)22- 6396 -7039 e-mail n.hanoi@nagoya-cut.co.jp https://www.nagoya-cut.co.jp/vn/ |

||

| Location |  |

|

| Established | July 1, 1992 | |

| Leadership | Toshihiro Hisha, President | |

| Capital | 10,000,000 JPY | |

| Sales | 500,000,000 JPY (2023FY) | |

| Employees | 30 people | |

| Banks | Ogaki Kyoritsu Bank Ichinomiya branch Hyakugo Bank Ichinomiya branch Ichii Shinkin Bank Ichinomiya branch Chukyo Bank Ichinomiya Minami branch Nagoya Bank Ichinomiya branch Aichi Bank Ichinomiya Minami branch Mitsubishi UFJ Bank Nagoya Main Office |

|

| Business | 【Applications for RAIDE CUT cutting dies】

|

|

| Main Products |

|

|

| brand |  |

|

| Core Competence |

|

|

| Certificates | “Aichi brand” company certificate (Certificate No. 606) |

ISO9001: 2015 certificate |

(as of March 2024)

Philosophy

Motto

- Be creative.

- Show sincerity.

- Nurture trust.

Philosophy

- We will make everyone happy by fostering creativity and ingenuity in our employees, and use the fusion of advanced technology and expert skills to realize the aim to be the first and only choice in the industry.

- Focus on global customer service by utilizing employee training and self-education.

- Guarantee product precision and punctual delivery to attain trust from our customers.

Management policy

- Increase sales expansion of optical film cutting technology using high-precision techniques for IT industries

- Develop our “Human Technology”

History

| Jul. 1992 | Established at 52, Asano Aza Shinmeishita, Ichinomiya, Aichi |

|---|---|

| Nov. 1992 | Registered as a corporation |

| Jul. 1997 | Moved to a newly built company building in 2-4-16, Takaki, Ichinomiya Started production of precision cutting mold for IT industries |

| Dec. 2002 | Stat production of engraving blocks |

| Jul. 2003 | Exhibited products at the industry-first FPD (Flat Panel Display) exhibition at Tokyo Big Sight |

| Oct. 2004 | Expanded current factory |

| Apr. 2005 | Exhibited products in the 2nd FPD (Flat Panel Display) exhibition at Tokyo Big Sight |

| Jun. 2006 | Project started for ISO9001 and 2000 certification |

| Nov. 2007 | Acquired ISO9001 and 2000 certification |

| Apr. 2008 | Exhibited products at the 18th Fine Tech Japan (Flat Panel Display Technology Exhibition) |

| May 2009 | Updated the ISO9001 certificate to the 2008 version |

| Nov. 2009 | Awarded by the Nagoya Industries Promotion Corporation |

| Feb. 2010 | Certified as an Aichi Brand Company |

| Sep. 2010 | Moved to newly established company building at 12, Minami Obori, Higashi Itsushiro, Ichinomiya |

| Apr. 2011 | Exhibited products at the 2nd Film Tech Japan (exhibition for functional film technology) |

| Apr. 2014 | Exhibited products at the 5th Film Tech Japan (exhibition for functional film technology) |

| Nov. 2015 | Exhibited products at the 5th “Tech Biz EXPO 2015” |

| May. 2018 | Joined the automotive nickel-metal hydride cell industry |

| Dec. 2018 | Exhibited products at the 7th “High Functional Materials Week“ (the 7th High Functional Plastic Exhibition) |

| Jan. 2020 | Entered into the automotive lithium-ion battery industry |

| Feb. 2020 | Expanded the factory at Head Office |

| Oct. 2020 | Established an overseas division |

| Jul. 2021 | Established temperature control rooms |

| Jan. 2023 | Commenced groundwork for production facility in Vietnam |

| Aug. 2023 | Announced the one-of-a-kind brand “RAIDE CUT” as proof of blade shape and manufacturing technology. |

| Sep. 2023 | Established a new factory and Vietnam branch in Hanoi, Vietnam |

| Feb. 2024 | Started production at our Vietnam Factory |

President,

President,